Correct fitting of silo bolts is critical for ensuring the stability of your storage facility. Excessive tightening these bolts can lead to deformation of the silo walls, while not torquing enough can result in leaks and structural weakness.

- Refer to your silo's manufacturer recommendations for the correct torque requirements.

- Utilize a calibrated torque wrench to achieve the specified torque value.

- Secure the bolts in a crosswise pattern for evenpressure.

- Examine the bolts regularly for any signs of loosening

Following these instructions will help you guarantee a safe and efficient silo operation.

Preventing Silo Bolt Corrosion: Best Practices stopping

Silo bolt corrosion can lead to structural damage, impacting the safety and integrity of your grain storage system. Thankfully, there are several best practices you can implement to combat this risk.

One crucial step is regular evaluation of your silo bolts. Look for signs of rust, corrosion, or any compromised connections.

Moreover, use a high-quality lubricant specifically designed for outdoor applications. This will help shield the bolts from moisture and environmental factors. Regularly washing the bolt surfaces with a suitable cleaning agent can also enhance their lifespan.

For optimal protection, consider using corrosion proof coatings on your silo bolts.

Remember, preventive|maintenance is here key to preventing silo bolt corrosion and ensuring the longevity of your grain storage equipment.

Understanding Silo Bolt Load Requirements Determining

Silo bolt load requirements are critical for ensuring the structural integrity and safety of agricultural structures. These bolts, responsible for connecting various components such as silo walls, roofs, and floors, must withstand significant forces imposed by wind loads, material weight, and other environmental factors.

To accurately determine the necessary bolt load capacity, engineers consider several key parameters. These include the size and design of the silo, the type of soil it's built on, prevailing wind speeds, and the intended use in the structure. Utilizing industry-standard calculations, engineers can establish precise bolt load requirements to prevent failure.

Properly sized and installed bolts are essential for maintaining a stable and secure silo throughout its lifespan. Neglecting to meet bolt load requirements can have devastating consequences, potentially leading to structural instability and catastrophic failure.

It's crucial to consult with qualified professionals whom specialize in silo design and construction to ensure that bolt load requirements are accurately assessed and implemented. Following recommended guidelines and adhering to building codes will ultimately guarantee the safety and longevity of your agricultural structure.

Selecting a Right Silo Bolt for Your Scenario

When it comes to securing your silo structure, choosing the appropriate bolt is paramount. Factors|Variables impacting your selection include the scale of your silo, the kind of material it's constructed from, and the external conditions it will face. Additionally, consider the weight the bolts must withstand and the rate of inspection required. Consulting with a certified engineer can help ensure you select the best bolt for your unique needs.

- Heavy-duty bolts are often selected for silos subject to extreme loads.

- Corrosion-resistant bolts are essential in exposed environments.

- Always verify that the bolts adhere to industry guidelines.

Tackling Common Silo Bolt Problems

Silo bolts are critical components in many industrial applications, guaranteeing the structural integrity of silos. However, these bolts can face a variety of issues over time due to factors like corrosion.

Common silo bolt concerns include sheared bolts, which can result in structural instability and potential injury.

It's crucial to frequently monitor silo bolts for any signs of damage and execute prompt repairs to prevent serious consequences.

A few simple troubleshooting steps can often fix common silo bolt concerns.

Listed below are some typical silo bolt concerns and their possible solutions:

liLoose bolts can be tightened using a wrench. Inspect for wear on the threads or nuts, and replace if necessary.

liStripped threads may require rethreading the bolt hole or using a helicoil insert. If the damage is extensive, consider replacing the entire bolt.

liSheared bolts need to be removed carefully and replaced with new ones of the same size and strength.

By understanding common silo bolt issues and taking timely action, you can guarantee the structural integrity and security of your silos.

Silo Bolt Lifespan of Silo Bolts: A Maintenance Guide

Securing the integrity of your storage facility relies heavily on the strength of its silo bolts. These crucial fasteners bear the weight of towering structures and demanding environmental factors. To ensure their long-term reliability, a comprehensive maintenance plan is essential.

Periodically examine your silo bolts for signs of corrosion. Look for surface deterioration and loosening. Tighten any compromised connections immediately to prevent further degradation.

- Apply a protective layer to the threads of your silo bolts with a suitable grease to minimize friction and prevent environmental adverse effects.

- Replace any damaged silo bolts promptly. Do not attempt to mend severely damaged bolts, as this could lead to catastrophic failure.

- Ensure a clean and dry environment around your silo bolts to minimize corrosion.

By following these maintenance practices, you can significantly increase the durability of your silo bolts and ensure the long-term safety and integrity of your storage facility.

Bradley Pierce Then & Now!

Bradley Pierce Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Barry Watson Then & Now!

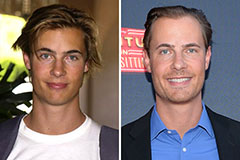

Barry Watson Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now!